Who we are

Cost Saving & Technical Assistance

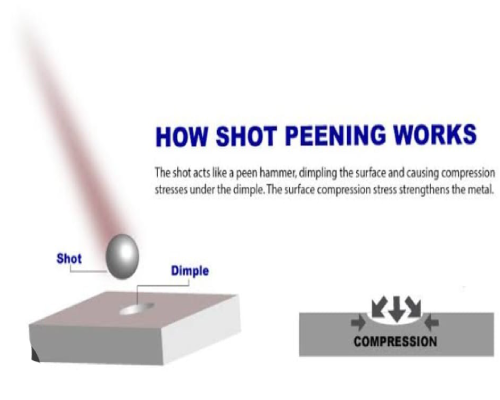

Our expertise helps in providing Quality Products and Services at comparatively most competitive Prices. We have a team of dedicated and specialized engineers to cater to any specific need of customers & to help customers in reducing the consumption of media in Shot Blasting Process & to increase the productivity .

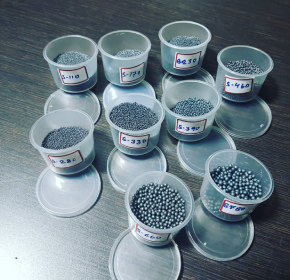

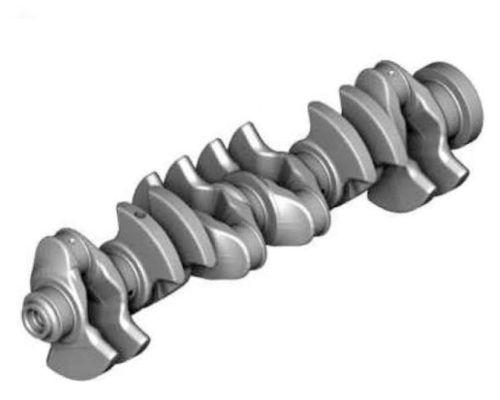

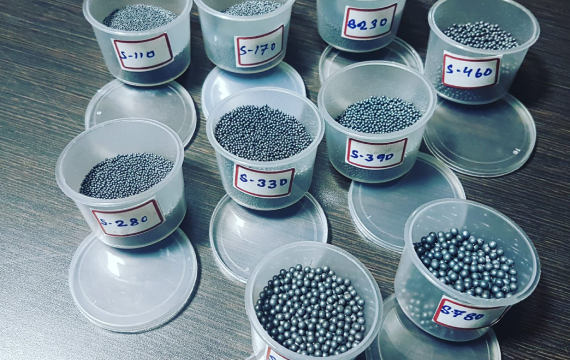

Our Most Selling Products

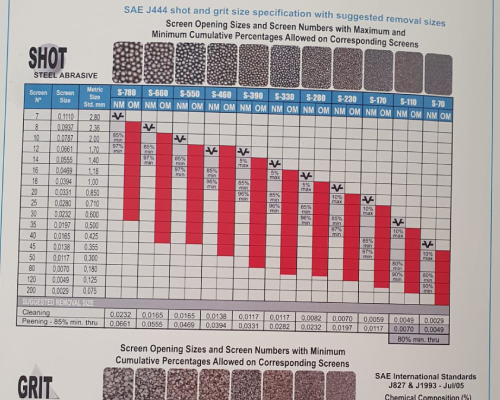

We have been supplying high Performance Steel Abrasives conforming to International Standards SAEJ444 , SAEJ441, SAEJ827, IS4606

Your Partner in Shot Blasting Excellence

Our Track Record Speaks for Itself

1995

+28 years of expertise

Get advantage of our unique abilities in shot blasting operations

20

Experts in the field

Let our application specialists guide you to optimize your process

10000

Customers

Get the best know-how on what is done in your industry

240

Agents and distributors

Get advantage of the biggest network in shot blasting

Quote from our clients

They trust us